Builders can eliminate a lot of firstyear warranty calls and latent defects by paying closer attention to seemingly minor details. A case in point is where different exterior finish materials and other products meet one another, such as stucco cladding at the frame of a vinyl door or window, or manufactured stone adjacent to an engineered wood trim board.

Simply, materials expand and contract at different rates in response to changes in moisture and temperature. Place them too close together, and one material’s expansion will intrude on another material reacting differently to the same conditions.

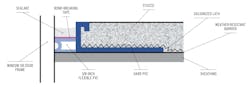

FIGURE 1: NO GAP BETWEEN DISSIMILAR MATERIALS

Photo: IBACOS

Where dissimilar materials meet—namely cementitious stucco, stone, or brick adjacent to wood-based or vinyl products—you need to purposely leave an adequate gap between them ... or risk surface cracking, window racking, or something far worse behind the finishes.

The problems caused by these cracks are twofold. First, they open a pathway for water to get behind the siding and into the wall system. Second, such surface cracks are often unsightly enough to get the homeowner’s attention, which leads to complaints and the impression that you practice poor quality assurance, causing the homeowner to search for other problems.

Add a Simple Detail

The best practice in all cases is to use vinyl J-channel or J-metal casing bead to adequately separate stucco, stone, or brick from wood or vinyl.

If you use J-channel, leave a ¼-inch gap between it and the window or trim, then fill it with backer rod and flexible sealant to create an engineered joint (Fig. 2, at right). The sealant needs to meet or exceed ASTM C920 Class 25. Apply the sealant before applying the stucco, and keep it clear as you install the cladding.

FIGURE 2: J-CHANNEL DETAIL

Photo: IBACOS

Even synthetic stucco expands and contracts at a different rate from vinyl or wood. The flexibility of the sealant and backer rod will compensate for that differential movement.

A J-metal casing bead also works as an effective separator, and it looks better in some applications (Fig. 3).

Training Trades

Unfortunately, siding contractors often ignore the gap. If they’re using stucco for the home’s siding, they bring it right up to the window or trim board (Fig. 1). And if they’re using manufactured stone, they may leave a small gap, but then fill it with mortar. It doesn’t take long for the differential movement to crack the stucco or mortar.

I could illustrate best practice details all day long, but the real challenge is getting your siding contractors to follow them on the jobsite. As with most things, the answer is to prioritize that detail for your siding subs.

FIGURE 3: J-METAL CASING BEAD DETAIL

Photo: IBACOS

Some builders blame poor material performance on turnover among their subcontractors’ crews, but I know builders that get it done right despite such turnover.

How? They have management systems that ensure these and other details are specified on every set of construction documents and that subcontractors determine their bids (or should) on those details. These builders also have site managers who clearly communicate expectations to subs, then inspect the work to make sure it’s done right.

Those builders also take a holistic view of cost. They understand that the small amount of money saved by leaving out that J-channel and sealant is a false economy when compared with the cost imposed on their warranty department and their reputation.

This piece originally ran as part of IBACOS and Pro Builder's joint "Quality Matters" series.

John Koenig drives quality and performance in home building as a building performance specialist of the PERFORM Builder Solutions team at IBACOS.