A Sustainable, Self-Powered Modern Farm House Built With ICFs

Two Chicagoans turned organic farmers made for perfect clients for sustainable architecture firm Tom Bassett-Dilley Architects (TBDA). The couples’ Wisconsin custom farmhouse, which is an actual farm, not just a home built in a farmhouse style, needed to reflect their lifestyle: healthy and good for the earth.

“A lot of our clients have a sense of mission," says architect Tom Bassett-Dilley, owner of the Oak Park, Ill., firm. "They feel like, ‘Well, if I'm going to build something and contribute to the world in this way, it should be something I can believe in and I can feel good about leaving something behind that will have lasting value.’ That was all motivation for [clients] Paul and Marisa.”

The home needed to be high-performance and produce energy for not just the family of four but their entire cattle farm, Starry Nights Farm. To achieve its net zero goal, the home uses insulated concrete form (ICF) construction and employed passive house principles in its design. Heat pumps and solar panels are part of the net zero package, and when the Wisconsin winters hit and test those heat pumps, a pellet stove helps keep indoor temperatures comfortable. All that energy efficiency is wrapped up in a modern farmhouse design with a quaint, thoughtful interior.

Material and Finish Selections for Healthy Indoor Air

The original plan for the home was to do a deep energy retrofit and remodel the existing farmhouse, but with a crumbling foundation, deteriorating surfaces, and structural awkwardness from old additions, building an entirely new home in place of the original structure became more realistic.

The new build needed to have a charming farmhouse aesthetic that would not look out of place on the property's sweeping 140 acres of farmland. The clients were comfortable with a traditional form and color for the structure, so the architect selected LP SmartSide board-and-batten siding. The siding’s prefinished, engineered-wood construction helps keep embodied energy low, and its durability and long warranty contribute to the product’s lifespan.

Bassett-Dilley worked closely with the clients to develop an interior design that embodies a warm minimalism while expressing the clients' unique character and maintaining a balance with the home's natural setting. “The idea for the house is that it's pretty much a backdrop to this incredible landscape,” Bassett-Dilley says.

The clients also required an extra bedroom, living room, and kitchen in the home's basement for agritourism, where Airbnb visitors can stay.

Shiplap, rustic woods, and textured tile help infuse the home's interiors with farmhouse style, and all specifications were made to ensure indoor health. TBDA selects building products based on Greenguard certification or the International Living Future Institute’s Declare label, down to the caulks and sealants used, such as AFM Safecoat products.

For paint, the firm specifies nontoxic, not just low-VOC, paints such as ECOS or Milk Paint.

Finding nontoxic cabinets can be challenging because many pre-made cabinets contain some formaldehyde, Bassett-Dilley says. To mitigate this, the architect selects custom cabinets built using formaldehyde-free plywood, such as PureBond from Columbia Forest Products.

Building With Insulated Concrete Forms

The client requested that the home be built with materials stronger than wood, so the team selected insulated concrette forms (ICFs). TBDA previously built two homes with ICFs and chose to work with Tim Pinter of Acts Construction, who uses Crown ICF, in Kenosha, Wis., collaborating early to tackle issues early on.

When building ICF homes, one important factor is ensuring air tightness, Bassett-Dilley says. Bringing Pinter on early helped to create a plan of attack for leaky areas such as window openings, wall-to-roof connections, wall-to-foundation connections, and course heights for the ICFs.

Bassett-Dilley and Pinter worked closely on visualizing and preparing for the intermediate floor connection where the floor is suspended from the walls, due to the potential for thermal bridging. It's important to understand the methods of each ICF system used to support a floor truss, as each one differs.

Window opening bucks also vary by ICF manufacturer. Some manufacturers use plywood, double plywood, or wood, and Bassett-Dilley says this is a critical detail to iron out ahead of time to ensure the team understands how to fasten the windows to the ICFs.

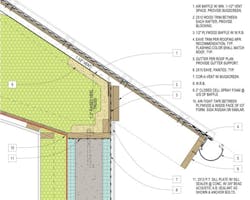

The air barrier for the roof trusses is another vital detail that needs to be prepared for in advance. In this home, the team installed plywood between the roof trusses and ICFs, leaving 1 1/2 inches of service cavity under that for electrical (see roof detail illustration, above). Then that barrier needed to be sealed off.

Critical in ensuring the home's air tightness was Phius (Passive House Institute US) energy rater Juanita Ellias, of River City Woodworking, in Milwaukee. A collaborative rater can provide valuable solutions, as Ellias did on this project.

“Juanita became a real advocate for the client and helped bring the contractors in line or to help troubleshoot any issues they had,” says Bassett-Dilley. “When you're on the construction site, thinking, ‘How am I going to get this to go here to there? How am I going to seal that?’ That's where the third-party rater can really help out.”

Using Pellet Stoves as Energy Backup

The architect selected an air source heat pump and heat pump water heater. The water heater also provides radiant heat to the basement slab, where the guest suite is.

But while extremely efficient, heat pumps can be challenged by the intense Wisconsin cold. Though they work, their efficiency drops. With this being an extremely tight passive house, the chances of any freezing are extremely low.

But as a safeguard, TBDA installed a couple of pellet stoves that use little of a home’s battery backup to ignite and are thermostatically controllable.

“They’re a good backup heat source,” Bassett-Dilley says. “They also provide radiant heat, which is a nice quality of heat when you can feel the heat coming off of something. So, we put one in the middle of the first floor, and it's a great feature on several levels: resilience, comfort, and peace of mind.”

The stoves burn pellets made from recycled sawdust that’s low carbon and inexpensive.

Solar Array and Power

To round out the net zero plan, TBDA placed a large solar array on the home’s south-facing standing-seam metal roof.

Though powering the home and farm may sound like a hefty energy demand, the clients’ organic regenerative approach to farming requires much less power, and they outsource refrigeration.

Architect: Tom Bassett-Dilley Architects

Structural Engineer: Olympic Engineering

Builder: Tim Pinter, Acts Construction, Crown ICF