Recognized for its good quality of life, stunning scenery and expansive views, Utah is ranked among the fastest growing housing markets in the U.S., with popular areas such as Salt Lake City and neighboring ski-destination Park City; each one coveted for their luxury homes and high-end real estate. Therefore, it’s no surprise that homeowners living in these upscale communities expect custom-built dwellings tailored to their individual liking — houses made from high-quality materials and burst with distinctive curb appeal that beautifully harmonizes with the surrounding landscape. Such was the case for two Utah homeowners.

Striking a Balance: Ensuring Durability and Ease of Installation While Maintaining Style

Luxury homeowners have discerning preferences and high expectations. Owners of the Park City-based “Red Ledges” project and the Salt Lake City “Retro” residence, each wanted a rustic, yet sleek, modern look. To meet their requirements, building professionals Viotell Metal Concepts (Red Ledges, Park City) and Aspen Roofing (Retro, Salt Lake City), respectively, searched for a material option that they were confident would produce a sturdy metal aesthetic and stand up to weather conditions.

“For Red Ledges, we needed an innovative solution that would make it possible for us to strike an ideal balance between durability, sophistication and affordability, while also delivering a finish that would coordinate brilliantly with a mix of other materials,” shared Anthony Ortega, chief operating officer, Viotell Metal Concepts. “Although ALUCOBOND PLUS is an aluminum composite material (ACM) known for its use on large commercial projects, I believed it checked all the boxes for this home, and utilizing the EasyFix System simplified the installation process for my crew.”

The Retro job was a mid-century modern home in need of an exterior refresh. However, its unique trim lines, expansive windows and existing masonry offered a challenge and required a designer’s eye and a craftsman’s approach to replacing the siding. Beyond these surface-level details, it was also a priority to select a cladding system – including a rainscreen – that would deliver moisture control and meet fire performance requirements.

“Our client wanted to give their house a facelift. We chose ALUCOBOND PLUS for its broad portfolio, which allowed us to perfectly match the finish of the owner’s much-loved rusted metal planter boxes that frame the home’s front elevation,” said Jon Brady, owner, Aspen Roofing. “Most importantly, the ALUCOBOND EasyFix system simplified the installation of the ACM panels, it was a solution that enabled our crew to carefully affix each section within tight spaces and unusual shapes.”

Traditionally installed on large-scale commercial buildings such as airports, schools and office buildings, ACM creates a refined, sturdy appearance that is typically achieved through an intricate extruded metal framework. ALUCOBOND PLUS, however, can be fitted using the ALUCOBOND EasyFix™ system, a cost-effective installation method that provides an aesthetic solution similar to traditional route-and-return systems that consist of all 4-sides returned and attached to extrusions at the fabricator. Instead, EasyFix boasts just two return sides that pair two types of folds - 135° and 90° - which reduces shop fabrication, enables straightforward field adjustments and results in faster installation. Panels are simply inserted into incrementally-spaced clips or a continuous rail.

This installation method creates value for residential builders and remodelers, while giving homeowners contemporary curb appeal and peace of mind that it will retain its smooth surface for years to come.

A Unique Fusion of Beauty and Performance

“Together, ALUCOBOND PLUS and the ALUCOBOND EasyFix System provided us with the products, tools and resources we needed to not only meet, but exceed, our clients’ expectations for their home exterior,” said Ortega. “Homeowners trust us with their biggest investment, and the demand for a metal home facade with fire retardant properties that will maintain its appearance and be as stunning years from now as it is on reveal day is understandable. We’re looking forward to continuing to offer and install ALUCOBOND to our clients.”

Contact Information:

3A Composites USA, Inc.

721 Jetton St. Suite 325

Davidson, NC 28036

USA

(800) 626-3365

info.usa@3acomposites.com

www.alucobondusa.com

Related Stories

Case Studies · sponsored

From Renovation to Rebuild: Finding Opportunity after Disaster

Custom Builder

Floodproof on a Floodplain

An impressive addition to the IDEA Home series, the NEWLOOK Experience Home is a master class in engineering and creative design, with builder Michael Freiburger out-thinking an exceptionally tricky lot

Case Studies

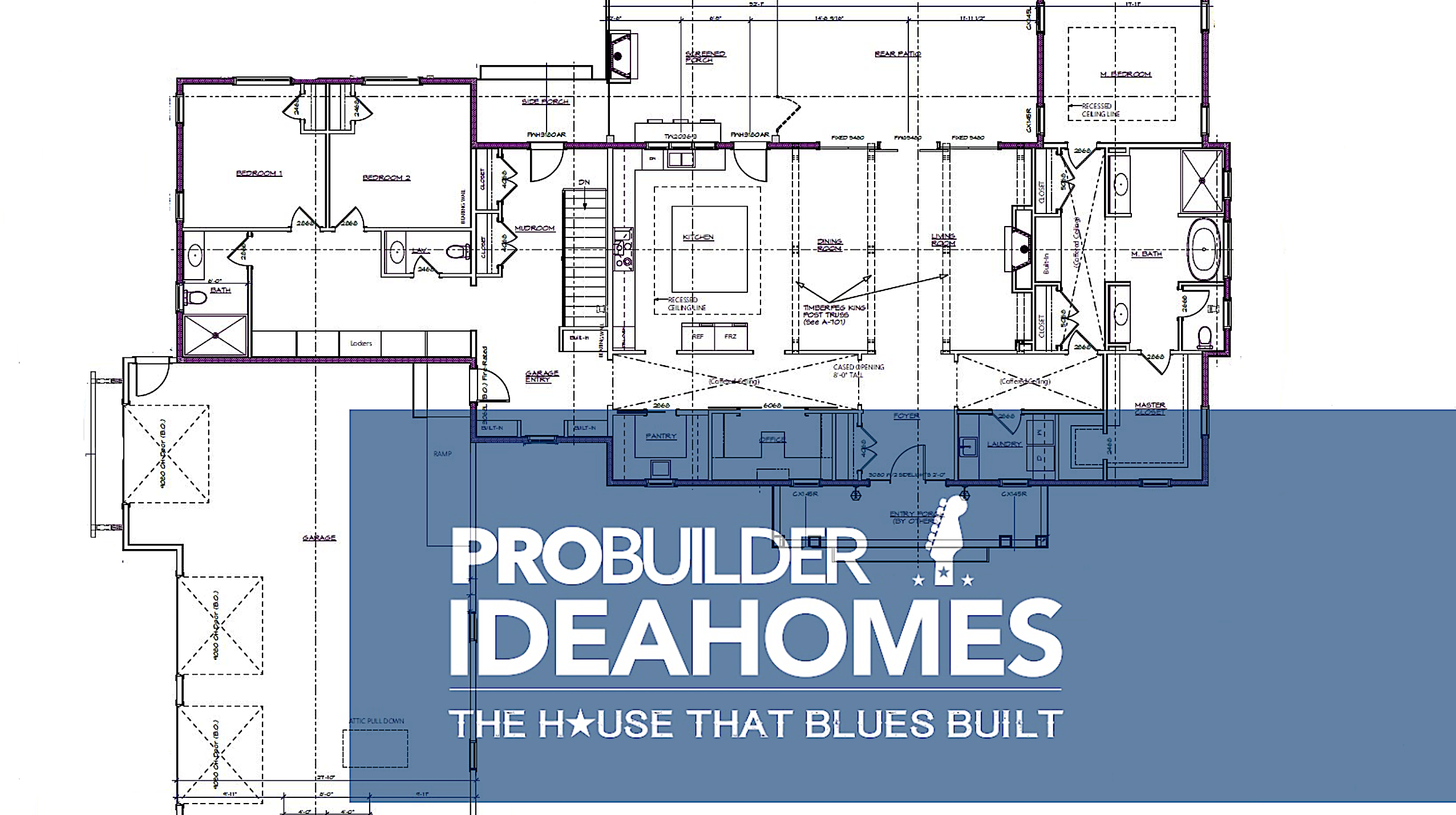

The House That Blues Built

Fourth-generation custom homebuilder Albert Cummings knows a lot about two things: building a high-performance home and performing the blues. See where the two meet in The House That Blues Built

Case Studies · sponsored

Crafting Utah's Luxury Landscape: ALUCOBOND Sets the Standard for Durable Custom Home Exteriors

Custom Builder

Telling a Story That Preserves the Past

Custom builder and historic restoration and preservation expert Brent Hull walks us through the careful details of his Pennsylvania Farmhouse project

Case Studies · sponsored

Building an Energy-Efficient Cabin with Nudura® Insulated Concrete Forms

Custom Builder

2023: A Year of Case Studies

A look back at the custom homes and craftsman details we spotlighted last year

Customer Service

A Smart Home Built Smart

Custom builder August Homes blends efficient, high-tech home automation systems with high-performance, sustainable building strategies

Case Studies

New Pandemic Task Force to Enhance Building Safety

A soon-to-be-appointed Pandemic Task Force seeks to strengthen the built environment in the face of disease-related threats

New Home

Hosting Multiple Generations for Generations to Come

Despite juggling numerous program and site considerations, architect Joel Wenzel designed a long-lasting, multi-generational retreat that nestles seamlessly into its bucolic surroundings